July 15, 2023

Applied Materials Inc Makes Significant Advancement in Semiconductor Manufacturing

Longstanding leader in semiconductor manufacturing platforms, Applied Materials, Inc. recently introduced their most advanced wafer manufacturing platform Vistara, the platform is the firm's most significant manufacturing innovation in the last decade. The Vistara platform is an important milestone in the company's long history of semiconductor manufacturing platforms which include Centris, Centura, Producer, and Endura. Vistara was developed over the span of more than 4 years and required the contributions of hundreds of the firm's engineers from across their software, hardware, process technology and ecoefficiency design teams. The new platform was designed to provide chip manufacturers with the flexibility, intelligence, and sustainability needed to tackle today's industry challenges. Vistara is able to use several different chamber types, sizes, and configurations and it can be configured to accommodate 4 or 6 wafer batch load ports as well as 4 to 12 process chambers, all of which allow it to adapt to a wide range of workloads. The platform also functions with smaller chambers used for processes such as atomic layer deposition and chemical vapor deposition as well as with larger chambers used for epitaxy and etching. Learn more about the Vistara platform here.

July 31, 2023

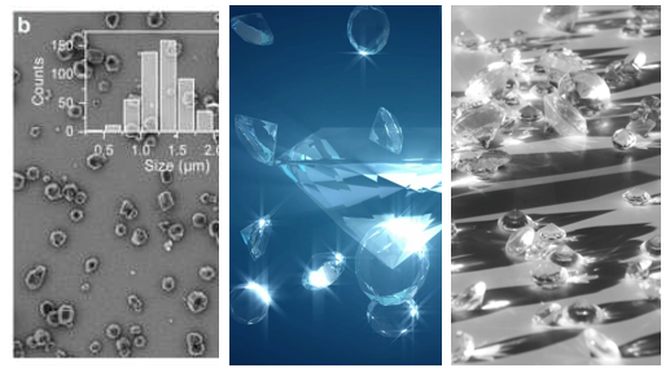

Diamond Based Labels to Put an End to Counterfeiting

Diamond Based Labels to Put an End to Counterfeiting

Researchers from the University of Hong Kong found a new way to prevent counterfeiting by using artificial diamond microparticles and Chemical Vapor Deposition to create diamond-based anti-counterfeiting labels. Counterfeiting is a major issue in various industries including electronics, medicine, and others. Counterfeit products pose threats to the health and safety of consumers and economic losses are also a major issue. Currently, counterfeiters and anti-counterfeiters are racing to develop technologies that will give them a competitive edge. The researchers are confident that counterfeiters will have no response to their new diamond based anti-counterfeiting labels. The labels are made by planting artificial diamond microparticles onto a silicon plate using chemical vapor deposition (CVD). The diamond particles are unique in size and shape; and when implanted on the silicon substrate they create a pattern that scatters light in a distinctive way, making the pattern impossible to replicate. The technology is also highly convenient and can be scanned and verified using only a smartphone. Additionally, diamond labels are very cheap to make costing only one dollar to make 10,000 labels. The researchers say the labels are ready to be used commercially. Learn more here.