To learn more about our company's Vacuum Deposition services, click here.

Scroll down for more content!

Scroll down for more content!

April 8, 2024

University in New York Receives New State of the Art Quantum Computer from IBM

University in New York Receives New State of the Art Quantum Computer from IBM

The Rensselaer Polytechnic Institute recently unveiled their new IBM System One quantum computer, which will be used for scientific discovery in fields including chemistry, physics, material science and other fields. The new quantum computer features an Eagle Processor that has 127 quantum bits (qubits). This novel quantum processing unit (QPU) was first revealed in 2021 and it made its official debut in a System One computer in November 2023 at University of Tokyo. IBM described their new quantum computer as “utility-scale” because it has sufficient power to serve as a scientific tool that will help scientists solve problems that conventional supercomputers could not. Technical program director for algorithms & partnerships at IBM Quantum said “When we describe “utility-scale,” we’re specifically referring to how quantum computers can now serve as scientific tools to explore new classes of problems in chemistry, physics, materials, and other fields that are beyond the reach of brute-force classical computing techniques.” he further mentioned that "Put simply, quantum computers are now better at running quantum circuits than a classical supercomputer is at simulating them. This means, for the first time in history, quantum computers can be used as a computational tool for scientific exploration." Learn more about this topic here.

April 22, 2024

MIT’s New Nanostitching Technique Could Have a Big Impact in the Aerospace Industry

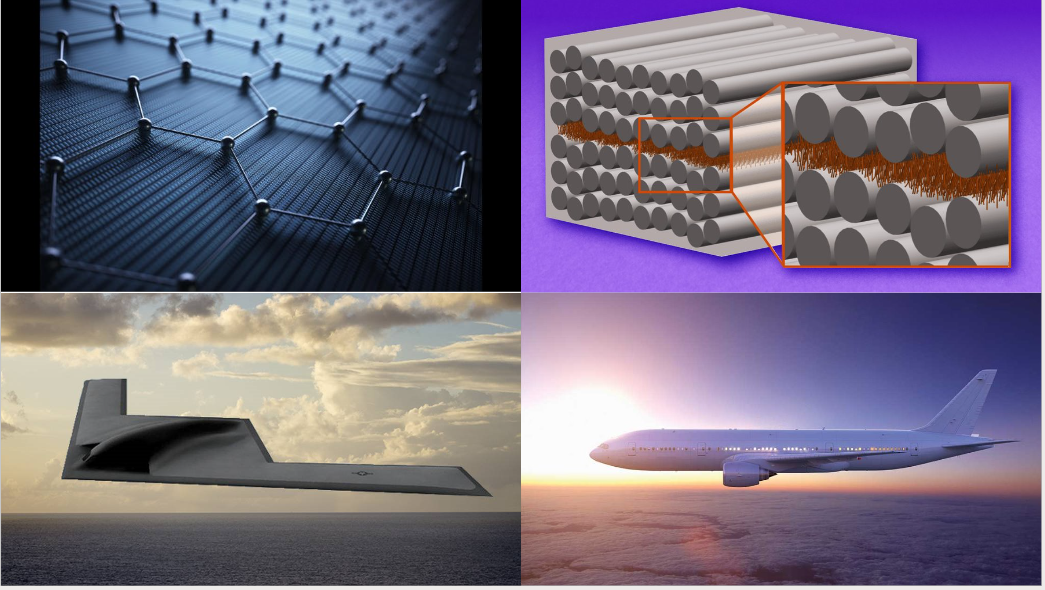

MIT’s New Nanostitching Technique Could Have a Big Impact in the Aerospace Industry

It is imperative that aircraft be strong, resistant, lightweight, and most importantly safe, this is why extremely tough materials are used to manufacture them. Such materials often include titanium, aluminum, steel, and composite materials such as carbon fiber or polymer. Composite materials are generally very light and extremely tough, two attributes that are highly sought after in the aerospace industry. It comes as no surprise that composite materials are commonly used in the aerospace industry, yet using such materials can present a complex challenge. Composites have layers and there is space between these layers, consequently engineers commonly use a specialized glue or other material to fill in the gaps. Nevertheless, composites can still become cracked and because they have various layers the damage may not be visible from the outside. MIT engineers have devised a better way of filling in these gaps, one that doesn't just use glue. The researchers are calling this new method “nanostitching”, and it works almost exactly as it sounds. To achieve it researchers first grow a forest of nanotubes, and then they use chemical vapor deposition (CVD) to make carbon settle onto a surface as tiny hair-like supports. Once the hairs are removed densely packed carbon nanotubes remain. These carbon nanotubes act as a bonding agent that keeps the layers bonded tightly together. The researchers tested the method on thin ply carbon fiber laminates and found that the nano stitched samples were 62 percent stronger and more resistant to cracks when compared to the same material held together with polymers. Learn more here.